We Are Main Pipe Experts

Neptune Coal Terminal Main Pipes Restoration

A Challenging Main Water Line Job

The Port of Vancouver has a multitude of service lines including water, electrical, and communications traveling under 12 railway tracks serving the port.

Four of these main lines were collapsed and could not be used. These power conduits are required to serve newly installed equipment.

The main contractor Lex Engineering who in turn subcontracted Drain Master to help develop a plan to re-establish these critical conduits under the railroad.

Drain Master was engaged to develop a plan and tools to open up these lines. These conduits had 4 offsets before the collapse which were located directly under active tracks.

We put together in their work shop a testbed with similar offsets.

Drain Master developed cutting heads and a driving mechanism to pass thru the offsets leading to the collapsed section of conduit.

A special head was designed that incorporated a camera, lighting, guide mechanisms, and a driver that could cut out the collapsed section.

A section of collapsed piping was produced in house with grout surrounding the conduit to demonstrate the tools in action.

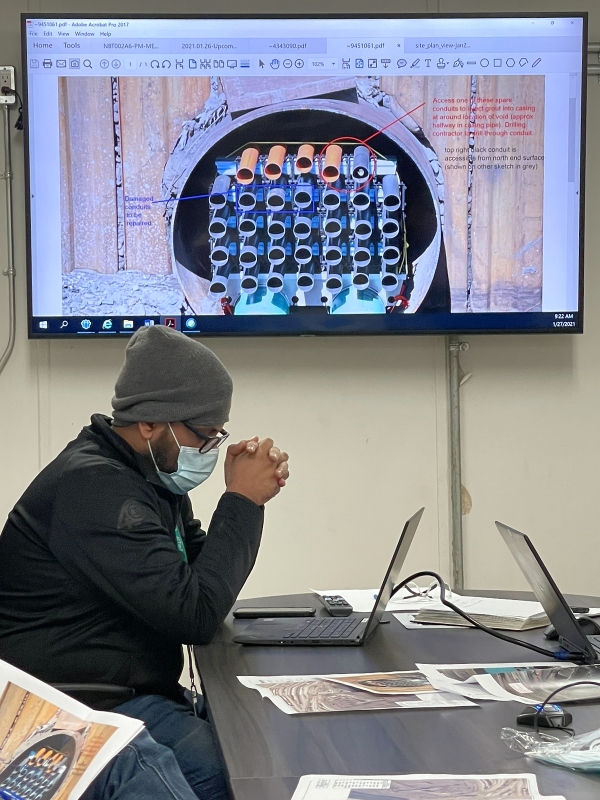

Key engineers from Neptune contractors along with Lex Engineering were invited to the demonstration.

The demonstration was successful and equipment was fine-tuned to move onto field operations.

Drain Master was dispatched and contracted to completely restore the underground conduits.

After several weeks the coring of the conduits was completed.

In the midst of machining out the collapsed sections of conduits, it was noted that critical grout was not surrounding them.

This grout is meant to disperse the heat produced when high amounts of power are required by the equipment.

Drain Master was then engaged to plan and execute the method of getting grout around the conduits.

A test station was developed at the work yard so the engineers could view the process.

The process was approved and then executed by technicians from Drain Master Plumbers.

When the grouting process was completed the conduits needed cleaning and conduits lined.

A fiberglass liner was inserted at all collapsed points to have a smooth inner surface finish.

Once this was complete it allowed Houle Electric the pathway to complete the electrical upgrades.

This project was very challenging for our team and saved the contractor from diverting the lines. This also saved them considerable costs.

Share It

Do you have a challenging job for us? No problem!

We've seen it all and have the right tools and staff to help you with any major water or sewer line issues.

See More Tough Jobs

Experience Peace of Mind with Our 25-Year Guarantee for Water Lines & 10-Year Guarantee for Sewer Lines!

We Guarantee Our Work - Drain Master Warranty.

Over 25 Years Experience Serving Greater Vancouver and the Lower Mainland

Other Services We Offer

Septic Tanks

Plumbing Inspections

Clean & Clear Plugged Drain

Live Video Drain Inspection

Water-Jet Drain Flushing

Pipe Replacement & Repair

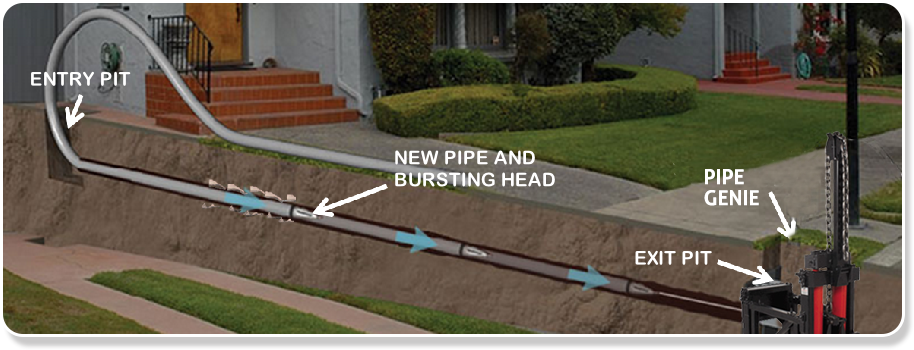

Pipe Bursting

Drain Cleaning

If you are in need of a Wet Basement repair, contact us today for a free estimate.

CONTACT US TODAY FOR A QUOTE!!